On-board diagnostics

On-Board Diagnostics, or OBD, in an automotive context, is a generic term referring to a vehicle's self-diagnostic and reporting capability. OBD systems give the vehicle owner or a repair technician access to state of health information for various vehicle sub-systems. The amount of diagnostic information available via OBD has varied widely since the introduction in the early 1980s of on-board vehicle computers, which made OBD possible. Early instances of OBD would simply illuminate a malfunction indicator light, or MIL, if a problem was detected—but would not provide any information as to the nature of the problem. Modern OBD implementations use a standardized fast digital communications port to provide realtime data in addition to a standardized series of diagnostic trouble codes, or DTCs, which allow one to rapidly identify and remedy malfunctions within the vehicle.

Contents |

History

- 1969: Volkswagen introduces the first on-board computer system with scanning capability, in their fuel-injected Type 3 models.

- 1975: Datsun 280Z On-board computers begin appearing on consumer vehicles, largely motivated by their need for real-time tuning of fuel injection systems. Simple OBD implementations appear, though there is no standardization in what is monitored or how it is reported.

- 1980: General Motors implements a proprietary interface and protocol for testing of the Engine Control Module (ECM) on the vehicle assembly line. The 'assembly line diagnostic link' (ALDL) protocol communicates at 160 baud with Pulse-width modulation (PWM) signaling and monitors very few vehicle systems. Implemented on California vehicles for the 1980 model year, and the rest of the United States in 1981, the ALDL was not intended for use outside the factory. The only available function for the owner is "Blinky Codes". By connecting pins A and B (with ignition key ON and engine OFF), the 'Check Engine Light' (CEL) blinks out a two-digit number that corresponds to a specific error condition. Cadillac (gasoline) fuel-injected vehicles, however, are equipped with actual on-board diagnostics, providing trouble codes, actuator tests and sensor data through the new digital Electronic Climate Control display. Holding down 'Off' and 'Warmer' for several seconds activates the diagnostic mode without need for an external scan-tool.

- 1986: An upgraded version of the ALDL protocol appears which communicates at 8192 baud with half-duplex UART signaling. This protocol is defined in GM XDE-5024B.

- ~1987: The California Air Resources Board (CARB) requires that all new vehicles sold in California starting in manufacturer's year 1988 (MY1988) have some basic OBD capability. These requirements are generally referred to as "OBD-I", though this name is not applied until the introduction of OBD-II. The data link connector and its position are not standardized, nor is the data protocol.

- 1988: The Society of Automotive Engineers (SAE) recommends a standardized diagnostic connector and set of diagnostic test signals.

- ~1994: Motivated by a desire for a state-wide emissions testing program, the CARB issues the OBD-II specification and mandates that it be adopted for all cars sold in California starting in model year 1996 (see CCR Title 13 Section 1968.1 and 40 CFR Part 86 Section 86.094). The DTCs and connector suggested by the SAE are incorporated into this specification.

- 1996: The OBD-II specification is made mandatory for all cars sold in the United States.

- 2001: The European Union makes EOBD mandatory for all petrol vehicles sold in the European Union, starting in MY2001 (see European emission standards Directive 98/69/EC [2] ).

- 2008: All cars sold in the United States are required to use the ISO 15765-4 [3] signaling standard (a variant of the Controller Area Network (CAN) bus).

- 2008: Certain light vehicles in China are required by the Environmental Protection Administration Office to implement OBD (standard GB18352[1]) by July 1, 2008[2]. Some regional exemptions may apply.

- 2010: HDOBD (heavy duty) specification is made mandatory for selected commercial (non-passenger car) engines sold in the United States.

Standard interfaces

OBD-I

The regulatory intent of OBD-I was to encourage auto manufacturers to design reliable emission control systems that remain effective for the vehicle's "useful life". The hope was that by forcing annual emissions testing for California , and denying registration to vehicles that did not pass, drivers would tend to purchase vehicles that would more reliably pass the test. OBD-I was largely unsuccessful, as the means of reporting emissions-specific diagnostic information was not standardized. Technical difficulties with obtaining standardized and reliable emissions information from all vehicles led to an inability to implement effectively the annual testing program.

OBD-1.5

OBD 1.5 refers to a partial implementation of OBD-II which General Motors used on some vehicles in 1994 and 1995 (GM did not use the term OBD 1.5 in the documentation for these vehicles - they simply have an OBD and an OBD-II section in the service manual.)

For example, the 94-95 Corvettes have one post-catalyst oxygen sensor (although they have two catalytic converters), and have a subset of the OBD-II codes implemented. For a 1994 Corvette the implemented OBD-II codes are P0116-P0118, P0131-P0135, P0151-P0155, P0158, P0160-P0161, P0171-P0175, P0420, P1114-P1115, P1133, P1153 and P1158.[3]

This hybrid system was present on the GM H-body cars in 94-95, W-body cars (Buick Regal, 94 Buick LeSabre, Chevrolet Lumina ('95 only), Chevrolet Monte Carlo ('95 only), Pontiac Grand Prix, Oldsmobile Cutlass Supreme) in 94-95, L-body (Chevrolet Beretta/Corsica) in 94-95, Y-body (Chevrolet Corvette) in 94-95, on the F-body (Chevrolet Camaro and Pontiac Firebird) in 95 and on the J-Body (Chevrolet Cavalier and Pontiac Sunfire) and N-Body (Buick Skylark, Oldsmobile Achieva, Pontiac Grand Am) in 95.

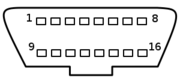

The pinout for the ALDL connection on these cars is as follows:

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

For ALDL connections, pin 9 is the data stream, pins 4 and 5 are ground and pin 16 is battery voltage.

An OBD 1.5 compatible scan tool is required to read codes generated by OBD 1.5.

Additional vehicle-specific diagnostic and control circuits are also available on this connector. For instance, on the Corvette there are interfaces for the Class 2 serial data stream from the PCM, the CCM diagnostic terminal, the radio data stream, the airbag system, the selective ride control system, the low tire pressure warning system and the passive keyless entry system.[4]

An OBD1.5 has also been used on Mitsubishi cars of '95 '97 vintage, some 1995 Volkswagen VR6's and in the Ford Scorpio since 95.[5]

OBD-II

OBD-II is an improvement over OBD-I in both capability and standardization. The OBD-II standard specifies the type of diagnostic connector and its pinout, the electrical signalling protocols available, and the messaging format. It also provides a candidate list of vehicle parameters to monitor along with how to encode the data for each. There is a pin in the connector that provides power for the scan tool from the vehicle battery, which eliminates the need to connect a scan tool to a power source separately. However, some technicians might still connect the scan tool to an auxiliary power source to protect data in the unusual event that a vehicle experiences a loss of electrical power due to a malfunction. Finally, the OBD-II standard provides an extensible list of DTCs. As a result of this standardization, a single device can query the on-board computer(s) in any vehicle. This OBD-II came in 2 models OBD-IIA and OBD-IIB.

OBD-II Diagnostic connector

The OBD-II specification provides for a standardized hardware interface—the female 16-pin (2x8) J1962 connector. Unlike the OBD-I connector, which was sometimes found under the hood of the vehicle, the OBD-II connector is required to be within 2 feet of the steering wheel (unless an exemption is applied for by the manufacturer, in which case it is still somewhere within reach of the driver). SAE J1962 defines the pinout of the connector as:

- Manufacturer discretion. GM: J2411 GMLAN/SWC/Single-Wire CAN.

- Bus positive Line of SAE-J1850 PWM and SAE-1850 VPW

- Ford DCL(+) Argentina, Brazil (pre OBD-II) 1997-2000, Usa, Europe, etc.

- Chassis ground

- Signal ground

- CAN high (ISO 15765-4 and SAE-J2284)

- K line of ISO 9141-2 and ISO 14230-4

- -

- -

- Bus negative Line of SAE-J1850 PWM only (not SAE-1850 VPW)

- Ford DCL(-) Argentina, Brazil (pre OBD-II) 1997-2000, Usa, Europe, etc.

- -

- -

- CAN low (ISO 15765-4 and SAE-J2284)

- L line of ISO 9141-2 and ISO 14230-4

- Battery voltage

The assignment of unspecified pins is left to the vehicle manufacturer's discretion.

EOBD

EOBD is a version of OBD-II required in Europe since Model Year 2003 for diesel vehicles and since 2001 for gasoline vehicles[6]. With Euro V and Euro VI emission standards, EOBD emission thresholds will be lower than previous Euro III and IV. EOBD refers to Europe On-Board Diagnostics.

EOBD2

The term "EOBD2" is a marketing term used by some vehicle manufacturers to refer to manufacturer-specific features that are not actually part of the OBD or EOBD standard.[6] In this case "E" stands for Enhanced.

JOBD

JOBD is a version of OBD-II for vehicles sold in Japan [7].

OBD-II Signal Protocols

There are five signalling protocols currently in use with the OBD-II interface. Any given vehicle will likely only implement one of the protocols. Often it is possible to make an educated guess about the protocol in use based on which pins are present on the J1962 connector:

- SAE J1850 PWM (pulse-width modulation - 41.6 kB/sec, standard of the Ford Motor Company)

- pin 2: Bus+

- pin 10: Bus–

- High voltage is +5 V

- Message length is restricted to 12 bytes, including CRC

- Employs a multi-master arbitration scheme called 'Carrier Sense Multiple Access with Non-Destructive Arbitration' (CSMA/NDA)

- SAE J1850 VPW (variable pulse width - 10.4/41.6 kB/sec, standard of General Motors)

- pin 2: Bus+

- Bus idles low

- High voltage is +7 V

- Decision point is +3.5 V

- Message length is restricted to 12 bytes, including CRC

- Employs CSMA/NDA

- ISO 9141-2. This protocol has an asynchronous serial data rate of 10.4 kBaud. It is somewhat similar to RS-232, but that the signal levels are different, and that communications happens on a single, bidirectional line without extra handshake signals. ISO 9141-2 is primarily used in Chrysler, European, and Asian vehicles.

- pin 7: K-line

- pin 15: L-line (optional)

- UART signaling (though not RS-232 voltage levels)

- K-line idles high

- High voltage is Vbatt

- Message length is restricted to 12 bytes, including CRC

- ISO 14230 KWP2000 (Keyword Protocol 2000)

- pin 7: K-line

- pin 15: L-line (optional)

- Physical layer identical to ISO 9141-2

- Data rate 1.2 to 10.4 kBaud

- Message may contain up to 255 bytes in the data field

- ISO 15765 CAN (250 kBit/s or 500 kBit/s). The CAN protocol is a popular standard outside of the US automotive industry and is making significant in-roads into the OBD-II market share. By 2008, all vehicles sold in the US will be required to implement CAN, thus eliminating the ambiguity of the existing five signalling protocols.

- pin 6: CAN High

- pin 14: CAN Low

All OBDII pinouts use the same connector but different pins are utilized with the exception of pin 4 (battery ground) and pin 16 (battery positive).

OBD-II diagnostic data available

OBD-II provides access to numerous data from the engine control unit (ECU) and offers a valuable source of information when troubleshooting problems inside a vehicle. The SAE J1979 standard defines a method for requesting various diagnostic data and a list of standard parameters that might be available from the ECU. The various parameters that are available are addressed by "parameter identification numbers" or PIDs which are defined in J1979. For a list of basic PIDs, their definitions, and the formulae to convert raw OBD-II output to meaningful diagnostic units, see OBD-II PIDs. Manufacturers are not required to implement all PIDs listed in J1979 and they are allowed to include proprietary PIDs that are not listed. The PID request and data retrieval system gives access to real time performance data as well as flagged DTCs. For a list of generic OBD-II DTCs suggested by the SAE, see Table of OBD-II Codes. Individual manufacturers often enhance the OBD-II code set with additional proprietary DTCs.

Mode of Operation

Here is a basic introduction to the OBD communication protocol according to ISO 15031:

Mode $01 is used to identify what Powertrain information is available to the scan tool.

Mode $02 displays Freeze Frame data.

Mode $03 lists the emission-related "confirmed" diagnostic trouble codes stored. It displays exact numeric, 5 digit codes identifying the faults.

Mode $04 is used to clear emission-related diagnostic information. This includes clearing the stored pending/confirmed DTCs and Freeze Frame data.

Mode $05 displays the oxygen sensor monitor screen and the test results gathered about the oxygen sensor.

There are ten numbers available for diagnostics:

- $01 Rich-to-Lean O2 sensor threshold voltage

- $02 Lean-to-Rich O2 sensor threshold voltage

- $03 Low sensor voltage threshold for switch time measurement

- $04 High sensor voltage threshold for switch time measurement

- $05 Rich-to-Lean switch time in ms

- $06 Lean-to Rich switch time in ms

- $07 Minimum voltage for test

- $08 Maximum voltage for test

- $09 Time between voltage transitions in ms

Mode $06 is a Request for On-Board Monitoring Test Results for Continuously and Non-Continuously Monitored System. There are typically a minimum value, a maximum value, and a current value for each non-continuous monitor.

Mode $07 is a Request for emission-related diagnostic trouble codes detected during current or last completed driving cycle. It enables the external test equipment to obtain "pending" diagnostic trouble codes detected during current or last completed driving cycle for emission-related components/systems. This is used by service technicians after a vehicle repair, and after clearing diagnostic information to see test results after a single driving cycle to determine if the repair has fixed the problem.

Mode $08 could enable the off-board test device to control the operation of an on-board system, test, or component.

Mode $09 is used to retrieve vehicle information. Among others, the following information is available:

- VIN (Vehicle Identification Number): Vehicle ID

- CALID (Calibration Identification): ID for the software installed on the ECU

- CVN (Calibration Verification Number): Number used to verify the integrity of the vehicle software. The manufacturer is responsible for determining the method of calculating CVN(s), e.g. using checksum.

- In-use performance counters

- Gasoline engine : Catalyst, Primary oxygen sensor, Evaporating system, EGR system, VVT system, Secondary air system, and Secondary oxygen sensor

- Diesel engine : NMHC catalyst, NOx reduction catalyst, NOx adsborber Particulate matter filter, Exhaust gas sensor, EGR system, VVT system, Boost pressure control, Fuel system.

Mode $0A lists emission-related "permanent" diagnostic trouble codes stored. As per CARB, any diagnostic trouble codes that is commanding MIL on and stored into non-volatile memory shall be logged as a permanent fault code.

Vehicle Communication Command modes 1 - 9, for OBD-II

Currently OBD-II defines 9 modes of operation, all 9 are supported by the APEX with specialized software to minimize communication overhead.

OBD-II Mode 1 Request data by PID Send 01XX(CR) CR=Carriage Return, ASCII code 13 XX= PID byte Receive Returns single message string – example V486B10410536CA(CR)

OBD-II Mode 2 Request Freeze Frame Data Send 02-PID-Frame-CR Frame is always 00 Receive single message string – example send 020000 – PID=00, show all supported Mode2 PIDs Rec. - V416B104200007F980000(CR)

OBD-II Mode 3 Request Trouble Codes Send 03(CR) Receive Single or multiple messages, refer to SAE-J1979 for complete specifications V0A416B104304010000000099 – indicates trouble code P0401

OBD-II Mode 4 Clear Codes and reset Malfunction Lamp Send 04(CR) Receive V486B10444436(CR) if successful, anything else means unsuccessful

OBD-II Mode 5 Legacy O2 Sensor Test Results Send 05 TID O2sensor CR -050001(CR) Receive Returns single message string – example: Send 050001(CR) Rec-V0B486B0E4500010000000108 (CR) If TID or O2 not supported then response will be V(CR) Refer toSAE-J1979 for full information

OBD-II Mode 6 Send For non-CAN systems send:06 TID – CR, TID=Test ID, usually defined by the vehicle manufacturer. For CAN vehicles send 06-#of TID’s-TID1-TID2….TID6 You should zero fill unused PIDs. Receive Returns single or multiple message string – example: Send-0600, Receive -V0B486B0E4600FF0001818109 (CR) – From ISO9141 Honda If TID not supported then response will be V(CR)~

For CAN, to get the results of TID 01, O2 Sensor Monitor Bank 1-Sensor 1, send 060101(CR), the vehicle replies: V101C4601010A0E68210000FFFF01800A2217401002FFFF 0123810E01CF00E60B24B8000000000000 Please see ISO-15031-5 for the description of the 28 byte reply.

OBD-II Mode 7 Pending Codes Send 07(CR) Receive Single or multiple messages, refer to SAE-J1979 for complete specifications.

OBD-II Mode 8 Control the operation of an on-board system, test or component. Send 08 TID DataA-DataB-DataC-DataD-DataE Receive V486B1048-TID-D0-D1-D2-D3-D4(CR) Example: Send 08010000000000(CR) Rec. V0A416B104801000000000085 A response of ‘VERR’ means the data buffer to transmit did not contain sufficient characters to form a message.

OBD-II Mode 9 Read VIN, Calibration Numbers. For NON-CAN OBD the VIN is 17 characters for vehicles that provide electronic access to the VIN. VIN characters shall be reported as ASCII values. The response consists of the following messages: Message #l shall contain three filling bytes of $00, followed by VIN character #l Message #2 shall contain VIN characters #2 to #5 inclusive Message #3 shall contain VIN characters #6 to #9 inclusive Message #4 shall contain VIN characters #lO to #13 inclusive Message #5 shall contain VIN characters #14 to #17 inclusive

Send 09-01-PID-(CR) Receive Send 090102(CR) to get VIN. Multiple messages, CAN Bus example : - response to 090102 for CAN communications V101449020131465421505731343532352246423235323338.

Legacy OBD Example: Send 0902(CR) Receive: V0A416B1049020539000000A30A416B1049020434363938DE0A416B1 049020333594E42AE0A416B1049020258313757F90A416B1049020131 46545278

In all cases, if the vehicle did not respond to an OBD request, only a ‘V’ followed by a (CR) will be sent. One more thing about the OBD-II communication. When a Mode 01, PID 00 command is issued, every OBD-II PCM in the vehicle will respond. Usually there is only one PCM, but some cars will have two, an engine controller and a transmission controller. This can lead to extra work in sorting out responses from multiple ECU’s when acquiring data. The APEX default settings will only receive bus messages from the lowest number ECU ( the Engine Controller) responding to a 00-01 command. This keeps the clutter out and simplifies user software.

OBD Applications

Various tools are available that plug in to the OBD connector to access OBD functions. These range from simple generic consumer level tools to highly sophisticated OEM dealership tools.

Hand-held scan tools

A wide range of rugged hand-held scan tools is available.

- Simple fault code readers/reset tools are mostly aimed at the consumer level. They may read simple error codes, possibly without translating the meaning, and reset those error codes.

- Professional hand-held scan tools may possess more advanced functions

- Access more advanced diagnostics

- Set manufacturer- or vehicle-specific ECU parameters

- Access and control other control units, such as air bag or ABS

- Real-time monitoring or graphing of engine parameters to facilitate diagnosis or tuning

PC-based scan tools and analysis platforms

A PC-based OBD analysis tool such as the Durametric[8] system use a proprietary adapter, or a more universal (in numbers manufactured) adapter. Interfaces may be opto isolated or not. Opto isolation can prevent ground loops between the vehicle under test and a ground of the PCs electrical system. The interface will convert the OBDII signals to serial data (USB or serial port) standard to PCs or Macs. The software then decodes the received data to a visual display.

In addition to the functions of a hand-held scan tool, the PC-based tool offers:

- Virtually unlimited storage capacity for data logging and other functions

- Higher resolution screen than handheld tools

- The ability to utilise multiple software programs adding flexibility

The extent that a PC tool may access manufacturer or vehicle-specific ECU diagnostics varies between software products as it does between hand-held scanners.

While a moderately priced cable/adapter may be used with free software (such as Opendiag[9], Freediag[10], and pyOBD[11]), the cost of some professional OBD software may match the cost of advanced hand-held tools.

Data loggers

Data loggers are designed to capture vehicle data while the vehicle is in normal operation, for later analysis.

Data logging uses include:

- Engine and vehicle monitoring under normal operation, for the purpose of diagnosis or tuning.

- Some US auto insurance companies offer reduced premiums if OBD-II vehicle data loggers[12] or cameras[13] are installed - and if the driver's behaviour meets requirements. This is a form of auto insurance risk selection

- Monitoring of driver behaviour by fleet vehicle operators.

Analysis of vehicle black box data may be performed on a periodic basis, automatically transmitted wirelessly to a third party or retrieved for forensic analysis after an event such as an accident, traffic infringement or mechanical fault.

Emission testing

In the United States, many states now use OBD-II testing instead of tailpipe testing in OBD-II compliant vehicles (1996 and newer). Since OBD-II stores trouble codes for emissions equipment, the testing computer can query the vehicle's onboard computer and verify there are no emission related trouble codes and that the vehicle is in compliance with emission standards for the model year it was manufactured.

Driver's supplementary vehicle instrumentation

Driver's supplementary vehicle instrumentation is instrumentation installed in a vehicle in addition to that provided by the vehicle manufacturer and intended for display to the driver during normal operation. This is opposed to scanners used primarily for active fault diagnosis, tuning, or hidden data logging.

Auto enthusiasts have traditionally installed additional gauges such as manifold vacuum, battery current etc. The OBD standard interface has enabled a new generation of enthusiast instrumentation accessing the full range of vehicle data used for diagnostics, and derived data such as instantaneous fuel economy.

Instrumentation may take the form of dedicated trip computers[14][15], carputer or interfaces to PDAs[16], smartphones[17], or a Garmin navigation unit[18].

As a carputer is essentially a PC, the same software could be loaded as for PC-based scan tools and vice-versa, so the distinction is only in the reason for use of the software.

These enthusiast systems may also include some functionality similar to the other scan tools.

Standards documents

SAE standards documents on OBD-II

- J1962 - Defines the physical connector used for the OBD-II interface.

- J1850 - Defines a serial data protocol. There are 2 variants- 10.4 kbit/s (single wire, VPW) and 41.6 kbit/s (2 wire, PWM). Mainly used by US manufacturers, also known as PCI (Chrysler, 10.4K), Class 2 (GM, 10.4K), and SCP (Ford, 41.6K)

- J1978 - Defines minimal operating standards for OBD-II scan tools

- J1979 - Defines standards for diagnostic test modes

- J2012 - Defines standards trouble codes and definitions.

- J2178-1 - Defines standards for network message header formats and physical address assignments

- J2178-2 - Gives data parameter definitions

- J2178-3 - Defines standards for network message frame IDs for single byte headers

- J2178-4 - Defines standards for network messages with three byte headers*

- J2284-3 - Defines 500K CAN Physical and Data Link Layer

- J2411 - Describes the GMLAN (Single-Wire CAN) protocol, used in newer GM vehicles. Often accessible on the OBD connector as PIN 1 on newer GM vehicles.

SAE standards documents on HD (Heavy Duty) OBD

- J1939 - Defines a data protocol for heavy duty commercial vehicles

ISO standards

- ISO 9141: Road vehicles — Diagnostic systems. International Organization for Standardization, 1989.

- Part 1: Requirements for interchange of digital information

- Part 2: CARB requirements for interchange of digital information

- Part 3: Verification of the communication between vehicle and OBD II scan tool

- ISO 11898: Road vehicles — Controller area network (CAN). International Organization for Standardization, 2003.

- Part 1: Data link layer and physical signalling

- Part 2: High-speed medium access unit

- Part 3: Low-speed, fault-tolerant, medium-dependent interface

- Part 4: Time-triggered communication

- ISO 14230: Road vehicles — Diagnostic systems — Keyword Protocol 2000, International Organization for Standardization, 1999.

- Part 1: Physical layer

- Part 2: Data link layer

- Part 3: Application layer

- Part 4: Requirements for emission-related systems

- ISO 15765: Road vehicles — Diagnostics on Controller Area Networks (CAN). International Organization for Standardization, 2004.

- Part 1: General information

- Part 2: Network layer services

- Part 3: Implementation of unified diagnostic services (UDS on CAN)

- Part 4: Requirements for emissions-related systems

See also

- OBD-II PIDs ("Parameter IDs")

- Engine control unit

References

- ↑ http://english.mep.gov.cn/inventory/Catalogue_Standards/200807/t20080718_125885.htm

- ↑ http://baike.baidu.com/view/171354.htm, Chinese news article on implementation of OBD (google translation http://translate.google.com/translate?hl=en&sl=zh&tl=en&u=http://baike.baidu.com/view/171354.htm)

- ↑ 1994 Corvette Service Manual, Book 2. General Motors Corporation. December 1993. pp. 6E3–A-166 : 6E3–A-223.

- ↑ 1994 Corvette Service Manual, Book 2. General Motors Corporation. Dec., 1993. pp. 6E3–A-11.

- ↑ EEC IV Code Reader: For 2.9L 12 Valve & Early Tdi, Ford Scorpio

- ↑ 6.0 6.1 KBM Systems - OBD Specifications :: OBD Introduction

- ↑ OBD2 FAQ: JOBD

- ↑ [1]

- ↑ Opendiag home page

- ↑ Freediag sourceforge page

- ↑ pyOBD home page

- ↑ http://www.progressive.com/myrate/myrate-default.aspx an auto insurer's OBD-II data-logging

- ↑ http://www.teensafedriver.com an auto insurer's in-car camera

- ↑ OBDuino open source OBD trip computer

- ↑ www.scangauge.com commercial OBD trip computer

- ↑ www.qcontinuum.org/obdgauge/index.htm open source PDA app showing OBD-based gauges

- ↑ http://devtoaster.com/products/rev/index.html commercial iPhone app showing OBD-based gauges

- ↑ https://buy.garmin.com/shop/shop.do?pID=38354 Garmin ecoRoute HD provides OBD II data via Bluetooth to compatible Garmin navigation units for display

- Notes

- Birnbaum, Ralph and Truglia, Jerry. Getting to Know OBD II. New York, 2000. ISBN 0-9706711-0-5.

- SAE International. On-Board Diagnostics for Light and Medium Duty Vehicles Standards Manual. Pennsylvania, 2003. ISBN 0-7680-1145-0.

External links

- SAE International OBDII is Copyrighted and the Full accurate and complete documentation on OBDII PID and Electronic inner workings of the On Board Diagnostics is available at the SAE website.

- ISO - International Organization for Standardization International Standards for Business, Government and Society. The OBDII standard is protected by international copyright laws, please be aware the information contained in this wiki is not complete and accurate information, you should download the Full PDF versions of the above documentation from the SAE and ISO website for full lists of Modes, Trouble Codes, and PIDs etc.

- National OBD Clearing House Center for Automotive Science and Technology at Weber State University

- United States Environmental Protection Agency OBD information for repair technicians, vehicle owners, and manufacturers

- OBD-II Codes Description OBD-II codes list, description and diagnosis.

- OBD-II Trouble Code Articles OBD-II trouble code technical articles for vehicle owners

- CAN Bus Equipped Vehicles Vehicle makes, models and years using OBDII CAN bus protocol.

- Obd2 Weblog Official blog about the obd2 standard and new

- Pinouts of OBD-2 interface at various vehicles

- Diagnostic Scanner

- OBDII Flasher

- OBD-II Datalogger